Table of Contents

Do you wish you could better utilise your warehouse space? Ever ponder how to boost Product Throughput Velocity or improve Order Picking Product?

There’s a lot you can do in the area of process improvement, particularly in Distribution Centres. Our consultants are able through process, equipment or Warehouse Layout changes, to deliver significant benefits in the areas of:

- Space utilisation

- Order fulfillment accuracy

- Headcount reduction

- Improved Order Picking Product

- Product throughput velocity

- Cost reduction

- Service improvement

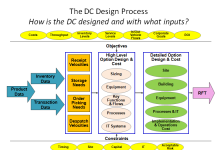

Warehouse & Distribution Centre Capacity & Productivity Modeling

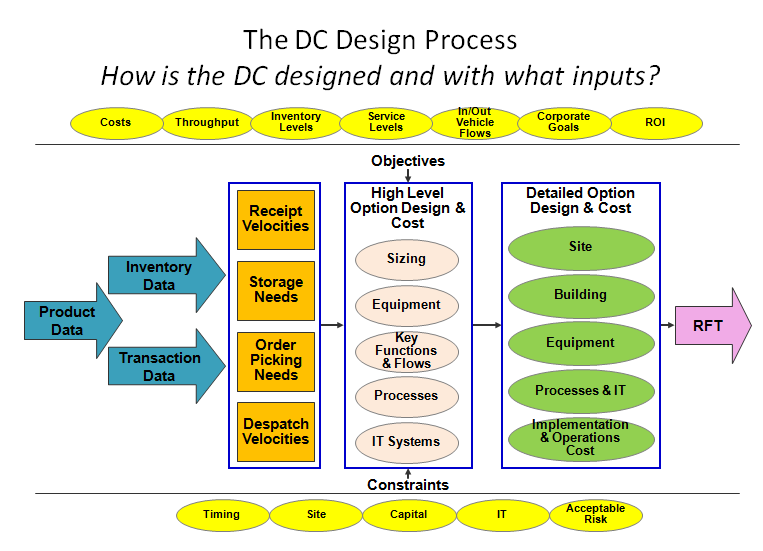

Many of our customers request that we assist them in modeling the capacity, or ‘useful life’ of warehouses and distribution centres. This can be a critical step in understanding the future needs of a growing business, and assessing the alternative methods of handling that growth.

Capacity models can be built to meet the specific needs of your business, and typically take account of the following:

- Inputs

- Product master data

- Demand data

- Key Capacity Drivers

- Receipt velocities

- Storage needs

- Order picking needs

- Despatch velocities

- Primary Constraints

- Space

- Equipment

- Processes

- Human resources

- Key Process Capacity Estimation

- Receiving

- Putaway

- Storage

- Picking

- Staging

- Despatch

- Assessment of Capacity Extension Options

- Improved DC processes

- Changed shift patterns

- Better use of the storage ‘cube’

- Altered supply processes

- Extensions to existing buildings

- Additional facilities